We are a group of companies operating under the names Roshan Qaderi, Zalmai Dawood Ltd, and Roshan Qaderi Construction Materials.

Our Services

Cement Activities and Representations

Zalmai Dawood Limited plays a leading role in the cement supply industry in Afghanistan. With extensive experience and expertise, we import high-quality cement from Pakistan, Iran, and Tajikistan to meet the growing needs of the Afghan construction sector.

In addition to our import operations, we proudly serve as the official representative of several reputable cement manufacturing companies, ensuring that their products meet both market demands and quality standards.

Official Representation of Ghori Cement (Afghanistan)

We are honored to have been the official representative of Ghori Cement, one of Afghanistan’s most renowned cement manufacturers, for over 7 years under a formal contract.

Ghori Cement is known for its strength, consistency, and adherence to international production standards. It is a preferred choice for both government and private sector projects across the country.

Key Features of Ghori Cement

- Manufactured to international standards

- High strength and long-lasting composition

- Ideal for infrastructure, residential, and commercial projects

- Fast-setting and cost-effective

- Reliable choice for both public and private sectors

Zalmai Dawood Limited remains committed to enhancing Afghanistan’s construction capabilities by providing access to premium cement brands through strong local and international partnerships.

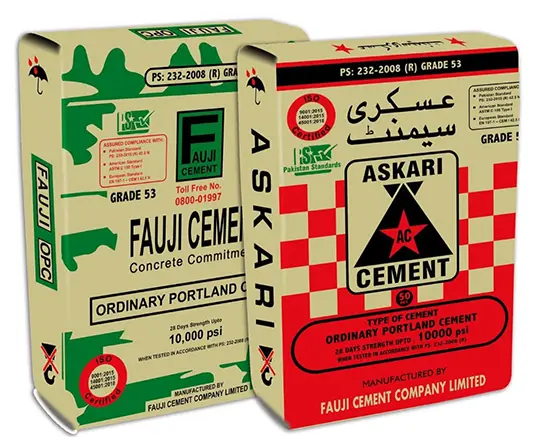

Official Representative of Pakistani Cement Brands

Zalmai Dawood Limited is proud to serve as the official representative of four of Pakistan’s most reputable cement manufacturers: Bestway Cement, Askari Fuji Cement, Lucky Cement, and Power Cement. These companies are known for producing high-quality, durable, and internationally certified cement, making them ideal for Afghanistan’s growing construction sector.

PK Leading Pakistani Cement Brands We Represent

Bestway Cement

Renowned for its high compressive strength, excellent bonding properties, and long-term durability. A trusted choice for infrastructure and industrial projects.

Askari Fuji Cement

A well-established brand offering standard-grade cement suitable for buildings, bridges, and major public and private construction projects.

Lucky Cement

A globally recognized name, Lucky Cement is known for its innovative technologies, consistent quality, and environmentally sustainable manufacturing.

Power Cement

Offers high-strength, cost-effective solutions ideal for residential, commercial, and economic-scale projects.

Why Choose Zalmai Dawood Limited?

- Cement products manufactured to international standards

- Ideal for a wide range of construction applications

- Assured quality, long-lasting performance, and competitive pricing

- Fast and reliable delivery across Afghanistan

At Zalmai Dawood Limited, we are committed to supplying the Afghan market with premium cement solutions that support the nation’s infrastructure development with quality, reliability, and trust.

Part 001

Iranian Cement Imports

Zalmai Dawood Limited is one of the leading importers of high-quality Iranian cement brands, including Bagheran, Sistan, and Qain Cement. We deliver reliable and cost-effective construction solutions to our clients across Afghanistan.

1. Bagheran Cement

Known for its exceptional strength and durability, Bagheran Cement is ideal for high-load structures such as buildings, bridges, and major infrastructure projects.

2. Sistan Cement

Produced in compliance with international standards, Sistan Cement offers long-lasting performance and is well-suited for a variety of construction applications.

3. Qain Cement

Offering a balance between high quality and affordability, Qain Cement is the preferred choice for residential and commercial building projects.

We import these trusted cement products directly from Iran and ensure our clients receive materials that meet the highest standards of quality and performance.

Official Representative of Tajcem Cement - Tojikcement

Zalmai Dawood Limited is the official representative of Tajim Cement, a renowned cement manufacturer in Tajikistan. We supply premium-grade cement products across Afghanistan for a wide range of construction needs.

Features of Tajcem Cement

- Complies with international quality standards

- Strong and reliable material for all types of construction projects

- Long-lasting durability and structural integrity

- Directly imported from Tajikistan

- Fast delivery and professional customer service across Afghanistan

Our Commitment

At Zalmai Dawood Limited, we are dedicated to supporting the development of Afghanistan’s infrastructure by importing and distributing high-quality construction materials. Our partnerships with reputable cement manufacturers reflect our commitment to:

- Quality assurance

- Customer trust

- Sustainable national progress

DG Cement

Zalmai Dawood Limited proudly imports DG Cement from Pakistan, including both Ordinary Portland Cement and Sulphate Resistant Cement.

1- Ordinary Portland Cement (OPC)

Exceptional Strength:

To ensure that cement dispatched to customers is with Zero defect quality and has exceptionally high strength superseding national and international standards, automatic quality control is done through online X-ray analyzer and computer controlled systems. Our focus is not only on the quality of cement dispatched but on the consistency of the high quality cement dispatched. We may further add that the Quality Control department carries out regular checks and analysis of various raw materials, intermediate products and final products in order to have additional quality checks. At DGKCC the chemical composition and grinding fineness are closely monitored to ensure that both Pakistani and British standards are surpassed and our customers get cement of exceptional strength.

Ideal Setting Time:

In order to allow sufficient time for application, cement must have a quick initial settings time. However, once in place, the final settings should not take too long. At DGKCC ideal initial and final setting times are maintained.

2- Sulphate Resistant Cement (SRC)

Low C3A Content

Sulphate salts present in some soils combine with moisture and tri-calcium aluminate (C3A) , one of the constituents of cement to form a compound known as Sulpho Aluminate off Hydrated Calcium. This compound is highly expansive and gradually results in the destruction of concrete. However, if a C3A content is very low, it is rendered inert and there is thus no reaction at all. British and Pakistani standards specify that in a Sulphate Resistant Cement, the C3A content must not exceed 3.5%. D.G Sulphate Resistant Cement has a much lower C3A content, making the cement highly effective against Sulphate attacks.

High Strength

As with any type of cement, strength is the fundamental property of Sulphate Resistant Cement. D.G. Sulphate Resistant Cement achieves high strength through finer grinding and better particle distribution. In term of strength,, it not only exceeds by far the standards specified for Sulphate Resistant Cement, but also exceeds those of Ordinary Portland cement.

Low Alkali Content

Certain aggregates contain alkali sensitive ingredients, which under unfavorable conditions, can result in expansion leading to cracking of concrete. The presence of alkali also causes staining and other undesirable effects on concrete. American Standards specify that cement can be termed low-alkali if its alkali content does not exceed 0.6%. D.G. Sulphate Resistant Cement has alkali content below 0.6 and a unique distinction of being a Sulphate Resistance Cement that can also be classified as low – alkali cement.